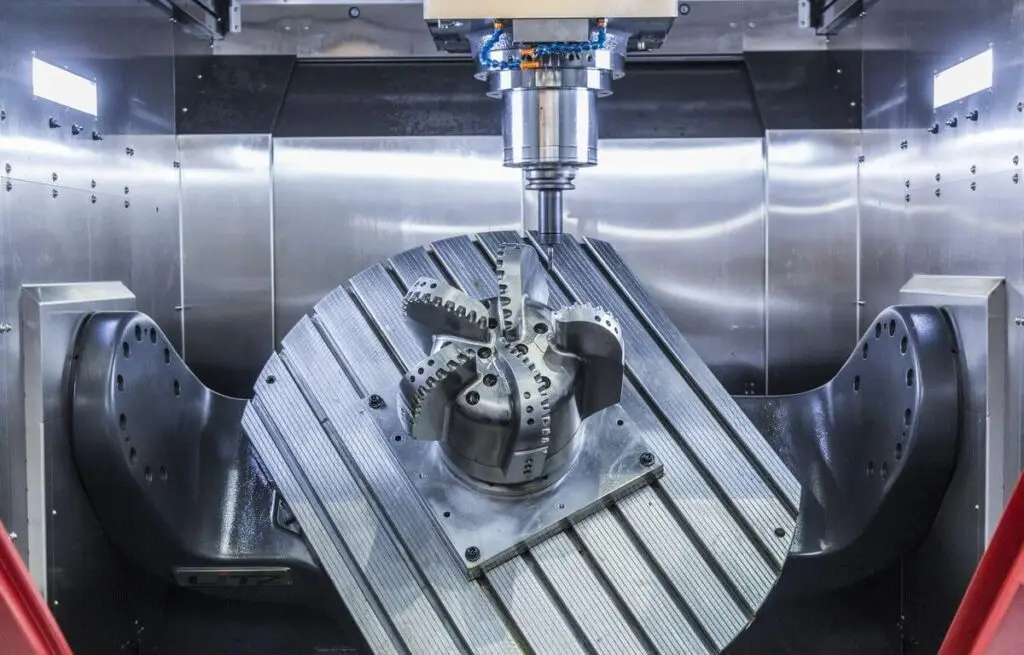

CNC machining delivers accurate and repeatable parts, but costs can climb quickly if designs are overly complex. Many of these costs come not from the machining itself, but from design choices that make production slower or harder. By making smart adjustments during the design stage, you can cut time and expense without affecting performance.

1. Use Rounded Corners Instead of Sharp Edges

Sharp internal corners force machinists to use smaller tools and slower passes. Adding a radius allows larger cutters, which shortens machining time and improves tool life. Rounded corners also produce smoother surfaces with less risk of chatter.

2. Limit Cavity Depth

Deep pockets require long, slender tools that are prone to deflection and wear. A practical guideline is to keep cavity depth less than four times its width. Shallower features not only save time but also improve accuracy and surface quality.

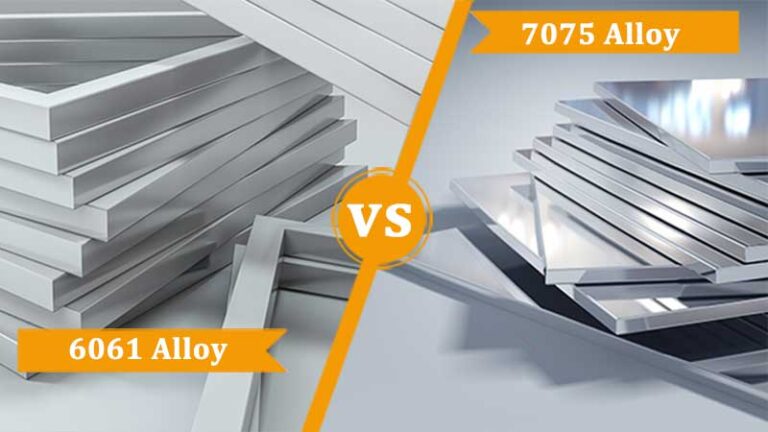

3. Keep Walls Thick Enough

Thin walls can flex or vibrate under cutting pressure, leading to poor tolerances or scrapped parts. For metals, keep walls no thinner than 0.8 mm; for plastics, 1.5 mm is a safer limit. Adequate wall thickness helps maintain dimensional stability.

4. Simplify Small Features

Very fine details—tiny holes, narrow slots, or decorative shapes—slow down machining and increase tool wear. If these features are not functionally necessary, consider removing or simplifying them. Cleaner geometry is always faster and less costly to produce.

5. Use Standard Hole Sizes

Standard drill diameters are faster and cheaper because they match readily available tooling. Non-standard holes often require special tools or multiple machining passes. Sticking with standard sizes speeds up production and reduces cost.

6. Control Thread Depth

Threads longer than three times the hole diameter rarely add strength. Extra depth only increases cycle time and tool wear. Keeping threads within functional limits is one of the easiest ways to reduce unnecessary machining.

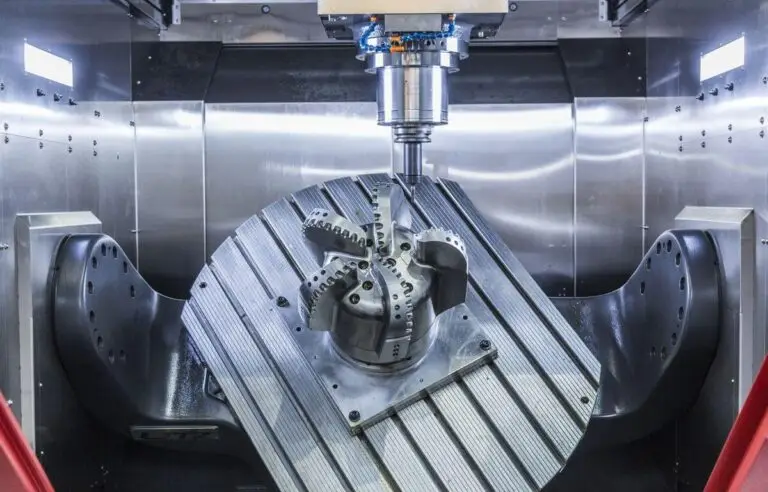

7. Reduce Setups Where Possible

Every time a part needs to be repositioned, costs rise. Re-clamping adds labor and introduces potential variation. Designing parts that can be machined in one or two setups improves consistency while keeping costs down.

Reducing CNC machining costs is less about cutting corners and more about making thoughtful design choices. Rounded features, reasonable depths, and simplified details help parts move smoothly from CAD to finished product. By applying these guidelines early in the design process, you can shorten machining time and keep budgets under control without sacrificing function.