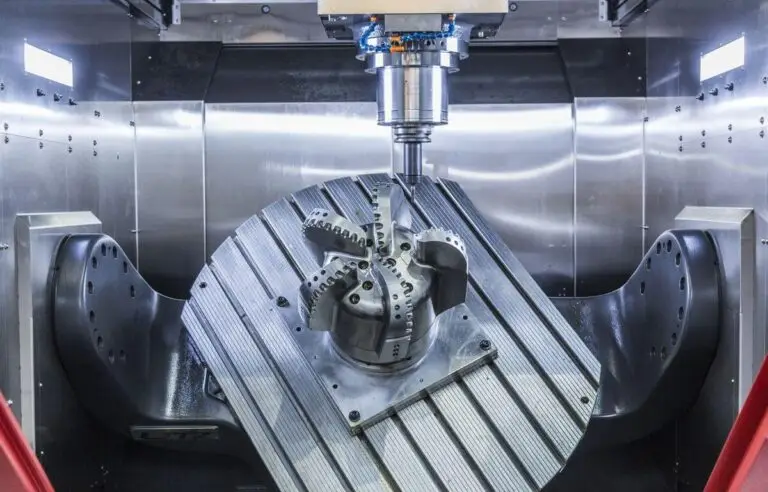

Surface finish is more than appearance—it directly affects how a machined part fits, seals, and performs. Rough or inconsistent finishes can cause assembly problems, friction, or even premature part failure. The good news is that many of these issues can be avoided with the right machining strategies.

Optimize Cutting Speeds and Feeds

During finishing passes, increase spindle speeds while reducing feed rates. This reduces built-up edges (BUE) and shortens tool–workpiece contact time, leaving a smoother surface. Fine-tuning cutting parameters is often the first step to improving finish quality.

Minimize Tool Chatter and Deflection

Chatter marks are one of the most common finish problems. To prevent them, use rigid tool holders, minimize tool overhang, and ensure the workpiece is firmly clamped. Less vibration means cleaner surfaces and longer tool life.

Control Chip Removal

Poor chip evacuation can scratch newly cut surfaces. Use chip breakers or geometries that curl chips into short, manageable shapes. Adequate coolant flow also helps remove chips quickly, protecting the finish and extending tool life.

Adjust Tool Geometry

A higher positive rake angle improves chip flow and reduces cutting forces, while a larger tool nose radius smooths out transitions on the surface. These adjustments help reduce visible tool marks and enhance overall finish quality.

Maintain Tools and Machines

Worn tools or poorly maintained machines are a common cause of poor surface finish. Keep cutting tools sharp, replace them before excessive wear, and perform routine machine maintenance to avoid spindle runout or vibration issues.

Apply Coolants and Lubrication Properly

Cutting fluids reduce friction, carry away heat, and help flush chips. The right coolant strategy prevents burn marks, tool wear, and other surface defects that occur under high-heat conditions.

Choose Suitable Tool Paths

Machining strategy affects finish. Climb milling generally produces smoother surfaces than conventional milling by reducing rubbing. Avoid sudden feed or depth changes that may leave tool marks.

Secondary Surface Treatments

Some parts require additional finishing after machining to meet visual or functional requirements. Common options include:

- Electropolishing for ultra-smooth surfaces.

- Media blasting (sandblasting or bead blasting) for a uniform matte texture.

- Anodizing or powder coating for corrosion resistance and appearance.

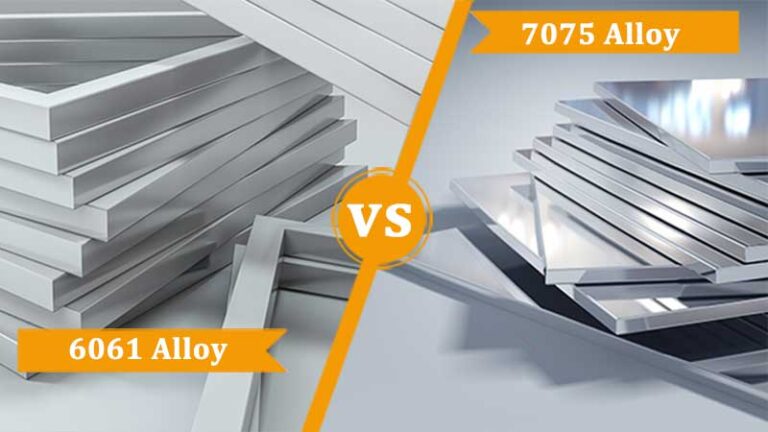

Material and Environmental Factors

Different materials behave differently under machining. Softer alloys may smear, while harder materials can chip or crack. Adjust feeds, speeds, and cooling methods according to the specific material and shop conditions.

Common Problems and Solutions for Surface Finish

| Problem | Likely Cause | Solution |

|---|---|---|

| Rough or uneven surface | Incorrect speeds/feeds | Increase spindle speed, reduce feed rate during finishing passes |

| Visible tool marks or chatter | Tool vibration or deflection | Use rigid tool holders, minimize overhang, secure workpiece tightly |

| Scratches on machined surface | Poor chip evacuation | Apply chip breakers, improve coolant flow for better chip removal |

| Excessive heat marks or burnishing | Insufficient coolant/lubrication | Use appropriate cutting fluids to reduce friction and temperature |

| Inconsistent finish across batches | Worn tools or poor machine condition | Maintain sharp tools, schedule regular machine maintenance |

| Dimensional lines or poor transitions | Small tool nose radius | Increase tool nose radius to smooth transitions |

| Rough finish on complex geometries | Inefficient tool paths | Use climb milling, optimize tool paths to avoid abrupt feed changes |

| Finish not meeting visual requirements | Base material limitations | Apply secondary finishing: electropolishing, blasting, anodizing, coating |

Achieving a good surface finish requires controlling every factor that touches the workpiece: speeds and feeds, tool geometry, chip removal, coolant, and even post-machining treatments. By combining these strategies, shops can avoid costly rework and deliver parts that meet both functional and aesthetic requirements.