Titanium is widely used in aerospace, medical, and automotive industries because of its excellent strength-to-weight ratio and corrosion resistance. Yet, its low thermal conductivity and tendency to work harden make it one of the more challenging metals to cut. Choosing the right cutting method is essential for achieving both efficiency and quality.

Here’s a detailed look at the main techniques for cutting titanium, along with tooling recommendations, heat-management strategies, and practical machine settings.

Manual and Saw Cutting

Manual cutting with hacksaws, shears, or abrasive wheels can work for small prototypes or simple shapes. However, it’s not efficient or precise enough for production.

Saw cutting with carbide or diamond-tipped blades is more effective for titanium stock. Cooling is critical because of the heat generated, and edges often need further finishing.

Pros: Simple equipment, low cost.

Cons: Limited precision, slower speeds, risk of rough edges.

Advanced Thermal Cutting

Laser cutting uses a focused beam for clean, accurate cuts with minimal distortion. Optimizing assist gases (nitrogen for clean edges, oxygen for faster cutting) improves results. Best for thin sheets and intricate profiles.

Plasma cutting relies on a high-velocity ionized gas stream. It handles thicker sections than lasers but creates a larger heat-affected zone. Argon provides precision, while nitrogen improves speed.

Electron beam machining (EBM) is highly precise, with minimal material waste, but requires vacuum conditions and specialized equipment. It’s mainly used for complex or high-value applications.

Pros: High accuracy (laser, EBM), handles thick materials (plasma).

Cons: Equipment cost, potential heat damage, need for gas or vacuum systems.

Non-Thermal Cutting

Waterjet cutting avoids heat altogether by using high-pressure water with abrasive particles. It can slice titanium up to 8 inches thick, preserving material properties and producing excellent surface finishes.

Pros: No heat-affected zone, high precision, good for thick parts.

Cons: Slower cutting speeds, higher operating costs.

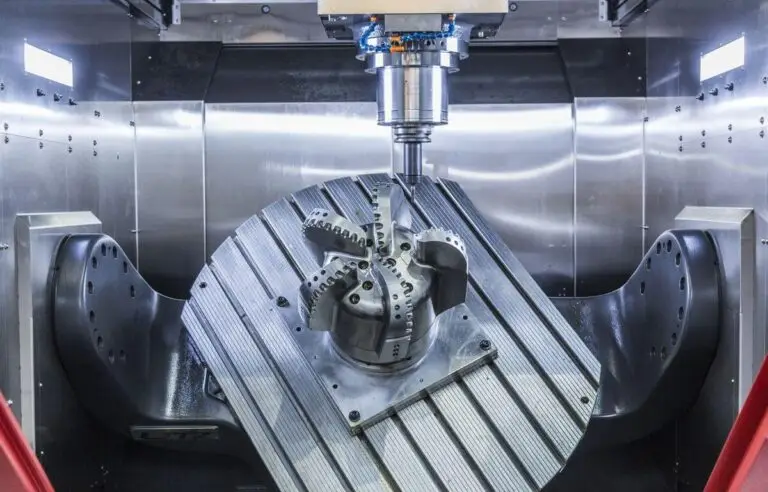

Machining Processes

Turning and milling are the backbone of titanium part production. Low cutting speeds, careful feed rates, and coated carbide tools (such as TiAlN) are essential. High-pressure coolant reduces heat buildup and prevents work hardening.

CNC machining automates turning, milling, drilling, and threading with high precision and repeatability. It’s ideal for complex geometries and production runs.

Pros: High accuracy, flexible for different geometries.

Cons: Tool wear, slower speeds required compared to softer metals.

Tooling and Coating Recommendations

Carbide tools are preferred for titanium because of their hardness and heat resistance. TiAlN or PVD coatings improve tool life by withstanding extreme cutting temperatures. Fine or medium-grain carbides with low binder content perform best under these conditions.

Heat Management and Cutting Challenges

Titanium’s poor thermal conductivity concentrates heat at the cutting edge. This accelerates tool wear and can cause work hardening. To manage this:

- Use low cutting speeds (around 90–100 SFM).

- Apply high-pressure coolant directly at the tool–workpiece interface.

- Favor shallow depth of cut with higher feed rates.

- Use climb milling to reduce friction and heat.

Cutting Speeds and Feeds

For most operations:

- Cutting speed: 90–100 SFM is typical.

- Feed rates: Higher feed with shallow cuts is recommended.

- Depth of cut: Small increments reduce heat buildup and extend tool life.

Common Failure Modes and Prevention

- Tool wear: Use coated carbide tools and proper cooling.

- Work hardening: Avoid rubbing cuts; keep feed rates steady.

- Thermal cracking: Control heat with coolant and conservative speeds.

- Dimensional inaccuracy: Ensure rigid setups and minimize vibration.

Pros and Cons of Cutting Methods

| Method | What it’s good for | What to watch out for |

|---|---|---|

| Manual Cutting | Low cost, simple tools | Low precision, slow, not scalable |

| Saw Cutting | Straight cuts on stock, affordable | Needs cooling, rough edges, limited accuracy |

| Laser Cutting | High precision, clean finish, narrow kerf | Limited thickness, expensive equipment |

| Plasma Cutting | Cuts thick sheets, faster than saw | Large heat-affected zone, less precision |

| Waterjet | No heat, excellent for thick sections | Slower speed, high operating cost |

| Turning/Milling | High accuracy, flexible shapes | Low speeds, tool wear, heat issues |

| CNC Machining | Automated, repeatable, handles complexity | Costly tools, requires skilled setup |

| EBM | Extremely precise, minimal waste | Specialized, expensive, vacuum required |

Titanium can be cut in many ways, but each method has trade-offs between speed, accuracy, cost, and material impact. Non-thermal methods like waterjet preserve properties, while laser and plasma excel in speed and efficiency. Machining with coated tools and strict heat management remains the standard for high-value parts.

By matching the method to the material thickness, design requirements, and production goals, manufacturers can achieve efficient and reliable titanium cutting.