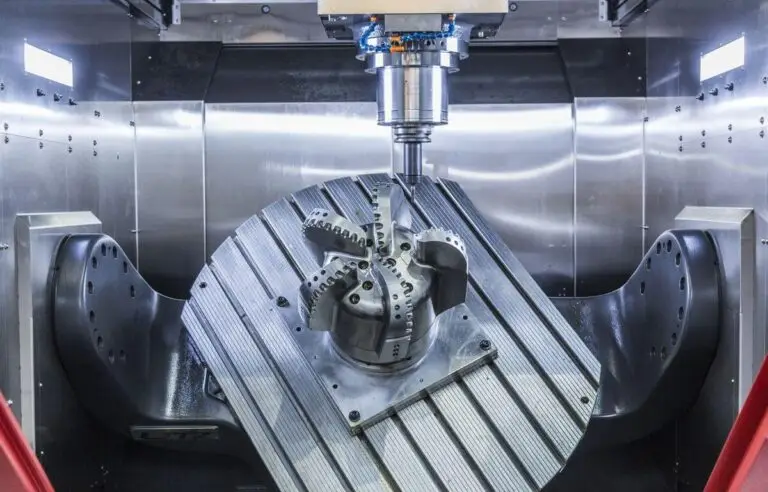

Fresh CNC machined parts often carry tool marks, sharp edges, and burrs. While these parts may meet dimensional requirements, they are rarely ready for end use. Surface treatments improve not only appearance but also durability, corrosion resistance, and even dimensional accuracy. The right finish depends on material, function, and cost.

Why Surface Treatments Matter

-

- Aesthetics: Removes machining marks and sharp edges, giving parts a professional look.

-

- Corrosion resistance: Essential for metals like steel or aluminum exposed to harsh environments.

-

- Wear resistance: Harder surfaces extend part life.

-

- Functionality: Some finishes add conductivity, friction control, or sterilizability.

-

- Dimensional control: Certain treatments reduce burrs or round off edges, improving fits.

Surface roughness is often measured by Ra (roughness average). As-machined CNC parts typically achieve Ra 125 µin (≈3.2 µm). With proper finishing, Ra can drop below Ra 32 µin (≈0.8 µm), suitable for sealing surfaces or optical applications.

Common Surface Finishing Methods

Bead Blasting

Propels fine glass beads to create a uniform matte finish. Good for aluminum housings and aesthetic parts. Not suitable for brittle plastics.

Powder Coating

Applies a durable polymer layer with color options. Provides strong corrosion protection and impact resistance, popular in consumer electronics, automotive, and outdoor equipment.

Electroplating

Deposits metals such as nickel, zinc, or chrome. Offers corrosion resistance and decorative appeal. Nickel plating is common for wear resistance; zinc for cost-effective protection.

Anodizing

Forms an oxide ceramic layer on aluminum and titanium.

-

- Type II (decorative anodizing): Adds color and moderate protection.

-

- Type III (hard anodizing): Thick coating for aerospace, automotive, and defense parts.

Polishing

Reduces surface roughness for a glossy look. Used in medical devices, food processing, and consumer products where cleanliness and aesthetics matter.

Brushing

Creates a linear matte texture, commonly seen on stainless steel kitchen equipment or aluminum panels.

Grinding and Wet Sanding

Used when smoother surfaces are needed before painting, coating, or high-gloss polishing.

Tumbling

Batch process that deburrs and smooths parts. Ideal for small hardware or fasteners, but not recommended for tight-tolerance components.

Passivation

Chemical process (often nitric or citric acid) that removes free iron from stainless steel, increasing corrosion resistance without changing dimensions.

Black Oxide

Forms a dark protective layer on steel. Reduces light reflection and adds mild corrosion resistance. Often used for tools and firearm components.

Electropolishing

An electrochemical method that dissolves a thin surface layer. Produces a very smooth, clean surface—ideal for sanitary, pharmaceutical, and semiconductor parts.

Specialized and Advanced Treatments

-

- Heat treatments: Case hardening, annealing, or tempering improve wear or mechanical properties.

-

- Chemical conversion coatings: Such as chromate conversion on aluminum (Alodine), enhancing conductivity and corrosion protection.

-

- PVD/CVD coatings: Titanium nitride (TiN) or diamond-like carbon (DLC) coatings improve hardness, wear resistance, and reduce friction.

-

- Laser engraving and silk screening: Add markings, part numbers, or branding without affecting part performance.

-

- Combination finishes: Brushing + electropolishing, anodizing + dyeing, or plating + passivation for specific needs.

Considerations for Selecting a Surface Finish

-

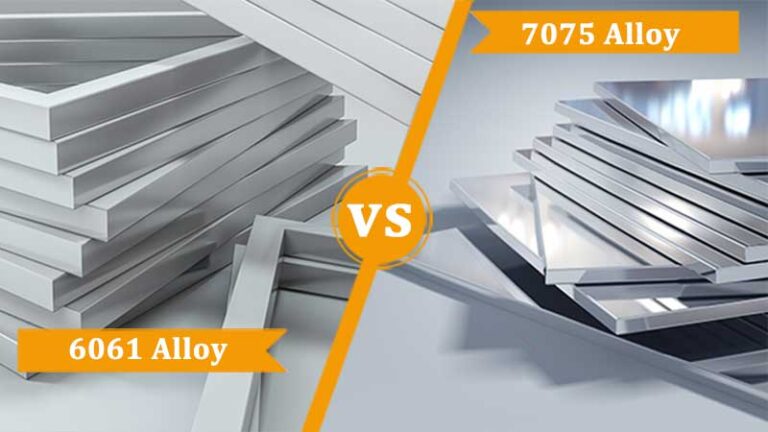

- Material compatibility: Anodizing only works on aluminum/titanium; passivation is for stainless steel; powder coating suits metals but not all plastics.

-

- Functional requirements: For marine parts, anodizing or electropolishing is best; for consumer products, powder coating or brushing may be preferred.

-

- Cost and lead time: Some treatments add multiple steps. Anodizing and bead blasting are relatively cost-effective, while PVD coatings or electropolishing can be expensive.

-

- Impact on tolerances: Anodizing can add ~0.0002”–0.001” (5–25 µm) per surface. Designers must account for dimensional changes.

Comparison of Common CNC Surface Treatments

| Method | Key Benefits | Typical Materials | Notes / Applications |

|---|---|---|---|

| Bead Blasting | Uniform matte finish, hides tool marks | Aluminum, steel | Enclosures, housings |

| Powder Coating | Corrosion & impact resistance, color | Metals | Outdoor, automotive |

| Electroplating | Corrosion resistance, decorative look | Steel, copper, brass | Hardware, fasteners |

| Anodizing (II) | Decorative, moderate protection | Aluminum, titanium | Consumer, aerospace |

| Anodizing (III) | Hard, wear-resistant coating | Aluminum, titanium | Aerospace, defense |

| Polishing | Smooth, glossy finish | Metals, plastics | Medical, consumer |

| Brushing | Matte linear texture | Stainless steel, aluminum | Appliances, panels |

| Tumbling | Deburring, smoothing | Small parts, fasteners | Batch finishing |

| Passivation | Enhances corrosion resistance | Stainless steel | Medical, food-grade |

| Black Oxide | Dark, non-reflective coating | Steel | Tools, firearms |

| Electropolishing | Ultra-smooth, easy-to-clean surface | Stainless steel | Pharma, semiconductor |

Practical Advice

Most CNC machined parts receive at least one finish—whether for looks, protection, or function. Start by defining what matters most: corrosion protection, surface smoothness, or aesthetics. Then match the right process to the material and budget.

For example:

-

- Aluminum housings → bead blasting + anodizing for matte, colored durability.

-

- Medical stainless steel parts → electropolishing for cleanability.

-

- Automotive brackets → powder coating for toughness and corrosion resistance.

Surface treatment is not an afterthought—it is often the final step that determines whether a part simply looks machined or is truly ready for service.