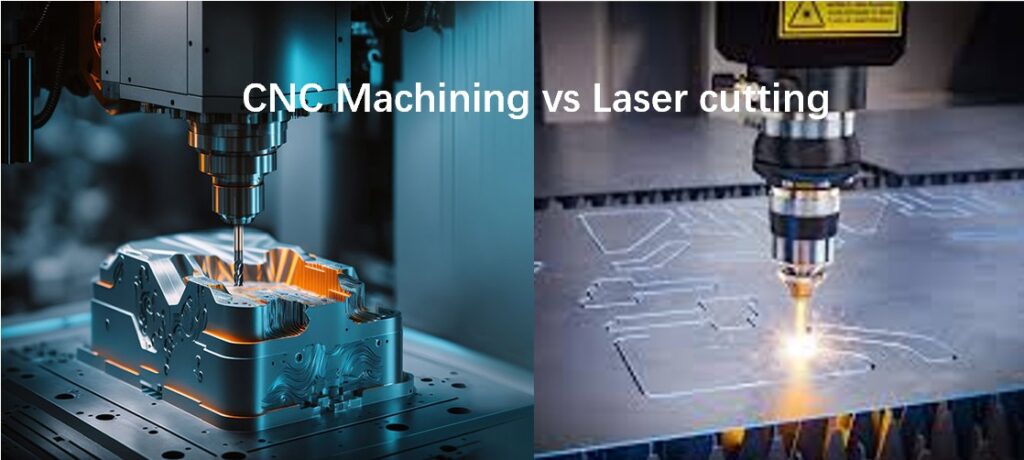

CNC machining and laser cutting are two of the most widely used methods for producing parts. At first glance they might seem interchangeable, but in practice they solve very different manufacturing problems. Knowing how they differ helps explain why certain industries rely on one process over the other.

Process Basics

CNC machining is a subtractive process that uses tools such as mills, drills, and lathes to cut away material. Because the cutting is physical and tool-driven, it is well suited for building solid parts with complex 3D shapes.

Laser cutting, by contrast, uses a concentrated laser beam to melt or vaporize material, usually in thin sheets or flat profiles. It is a non-contact thermal process that excels at fast, intricate 2D work.

Precision and Accuracy

Laser cutting offers extremely high precision for thin materials and detailed designs, with tolerances as tight as ±0.0005 inches. This is why it is common in electronics and decorative work, where fine detail matters.

CNC machining achieves tolerances in the ±0.001 to ±0.005 inch range and is especially strong in 3D geometries—pockets, bevels, or stepped cuts that cannot be made with a laser. Aerospace and medical parts often depend on this level of dimensional control.

Material Compatibility

CNC machines can handle nearly any machinable material—metals, plastics, composites, even wood—and are not limited by thickness. This flexibility makes them the default choice for heavy components such as steel fixtures or titanium aerospace parts.

Laser cutting works best on thin sheets, generally up to about 20mm thick. It struggles with reflective materials like copper or brass, but performs exceptionally on carbon steel, stainless steel, and aluminum sheet used in automotive and consumer goods.

Cutting Speed and Efficiency

For thin, flat stock, laser cutting is usually much faster than machining. It can slice complex outlines in seconds without tool changes, which is why sheet metal fabrication shops rely on it.

When parts are thick or require 3D geometry, CNC machining is more efficient. Milling a block of aluminum into a housing, for example, is far more practical with CNC than with any laser process.

Surface Finish and Edge Quality

Laser cutting produces smooth, burr-free edges and very narrow kerfs, making it ideal for parts that need little or no post-processing.

CNC machining often leaves tool marks, especially on intricate shapes, so secondary finishing like bead blasting or polishing may be required. On the other hand, CNC allows control of surface textures in ways laser cutting cannot.

Setup and Tooling

CNC machining depends on physical tooling that must be set up, calibrated, and replaced as it wears. This adds preparation time but also makes the process extremely versatile.

Laser cutting requires minimal setup. Since there are no cutting tools in contact with the material, there is no tool wear to manage—just programming and beam calibration.

Thickness and Dimensional Limits

One of the strongest differences lies in scale. Laser cutting is limited to relatively thin sheets. CNC machining has no practical thickness limit and can work on very large or heavy parts, from automotive engine blocks to industrial molds.

Thermal Effects

Because laser cutting is a heat-based process, it can create heat-affected zones or warping on sensitive materials. Ventilation is also needed to handle fumes.

CNC machining is mechanical and produces little thermal distortion, but it does generate chips that must be collected and recycled.

Cost Considerations

Laser cutting systems are expensive to purchase, but for thin sheet work they have low operating costs and need less labor due to automation.

CNC machining can be more costly in terms of tooling wear and machine time, but its ability to handle a wide range of parts makes it cost-effective for jobs where geometry or thickness rules out lasers.

Applications

Laser cutting is most often used in sheet metal fabrication, electronics, automotive interiors, signage, and decorative work—applications where speed and fine detail matter.

CNC machining is used for prototypes, aerospace structures, precision medical devices, and any part that requires 3D complexity, tight tolerances, or thicker materials.

CNC Machining vs Laser Cutting: Quick Comparison

| Factor | CNC Machining | Laser Cutting |

|---|---|---|

| Process | Physical cutting tools remove material | High-energy laser beam melts/vaporizes material |

| Precision | ±0.001 to ±0.005 in; strong in 3D features | ±0.0005 in; best for thin sheets and 2D cuts |

| Material Range | Metals, plastics, composites, wood; any thickness | Best for thin sheets (≤20 mm); struggles with reflective metals |

| Speed | Slower on thin sheets, efficient on thick parts | Very fast on thin, flat materials |

| Surface Finish | May need secondary finishing; tool marks possible | Clean, burr-free, narrow kerf width |

| Setup & Tooling | Requires tooling, setup, and calibration | Minimal setup, no tool wear |

| Thickness Limit | No practical limit | Limited to thin sheets |

| Thermal Impact | Low thermal effect, produces chips | Heat-affected zone possible, risk of warping |

| Cost | Tooling wear and higher setup costs; versatile use | High machine cost, low operating cost for thin parts |

| Applications | Aerospace, automotive, medical, prototypes | Sheet metal, electronics, signage, decorative work |

Both CNC machining and laser cutting are powerful manufacturing methods, but they serve different needs. CNC machining is the go-to for complex 3D parts, thick materials, and tight tolerances. Laser cutting is unbeatable for fast, precise cutting of thin sheets and intricate patterns. The right choice depends on part geometry, material type, and production goals.