When selecting a manufacturing technique for your prototyping needs, it’s essential to consider the precision and size capabilities of CNC machining and 3D printing. Here’s a comprehensive look at how these methods differ in terms of processing accuracy and maximum size capabilities.

Processing Accuracy

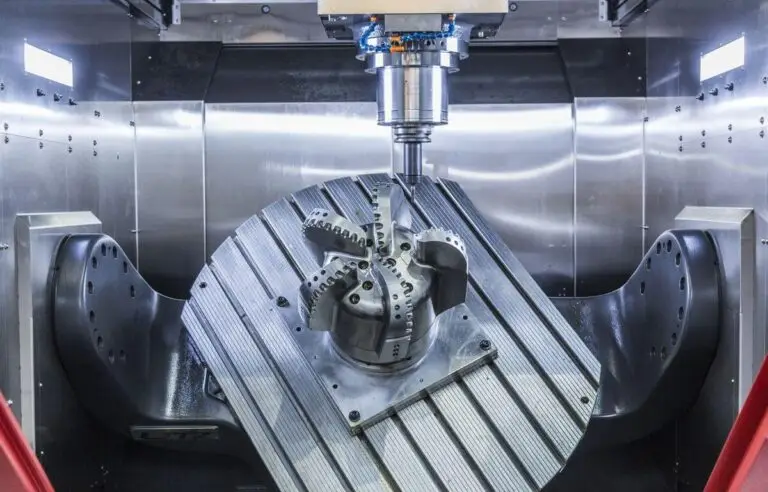

CNC Machining Precision

CNC machining is renowned for its high precision and accuracy. These machines can achieve tight tolerances, often around +/- 0.005 inches (0.127mm) or better. This makes CNC machining the preferred choice for applications where exact dimensions are crucial, such as in aerospace, automotive, and medical device manufacturing. The high precision ensures that every part produced meets strict quality standards, reducing the need for additional adjustments or rework.

3D Printing Precision

While 3D printing has significantly advanced in recent years, it generally cannot match the precision levels of CNC machining. However, it can still achieve impressive accuracy, especially with technologies like SLA and SLM. These 3D printing methods can produce parts with fine details and complex geometries, making them ideal for prototypes and intricate designs that do not require extremely tight tolerances.

Processing Size

3D Printing Size Limitations

The size of parts that can be produced with 3D printing is limited by the printer’s build volume. For instance:

- FDM Printers: Typically have a maximum build size of around 300mm x 300mm x 300mm.

- SLA Printers: Generally offer a larger build volume, up to 600mm x 600mm x 400mm.

These size constraints mean that very large parts might need to be printed in sections and assembled afterward, which could introduce weaknesses or inaccuracies.

CNC Machining Size Flexibility

CNC machining, on the other hand, offers greater flexibility in terms of part size. The maximum size is determined by the machine and workpiece accommodation capabilities. Some CNC machines can handle workpieces several meters in length, making them suitable for producing large components in a single piece. This flexibility is particularly useful in industries where large, high-precision parts are required.

Choosing Based on Precision and Size

When deciding between CNC machining and 3D printing, consider the precision and size requirements of your project. If your prototype demands tight tolerances and large-scale production, CNC machining is likely the better option. Conversely, if you need to create a complex, detailed model quickly and size constraints are less of a concern, 3D printing might be the way to go.

By understanding these differences, you can choose the manufacturing method that best aligns with your project’s specific needs, ensuring high-quality results and efficient production processes.