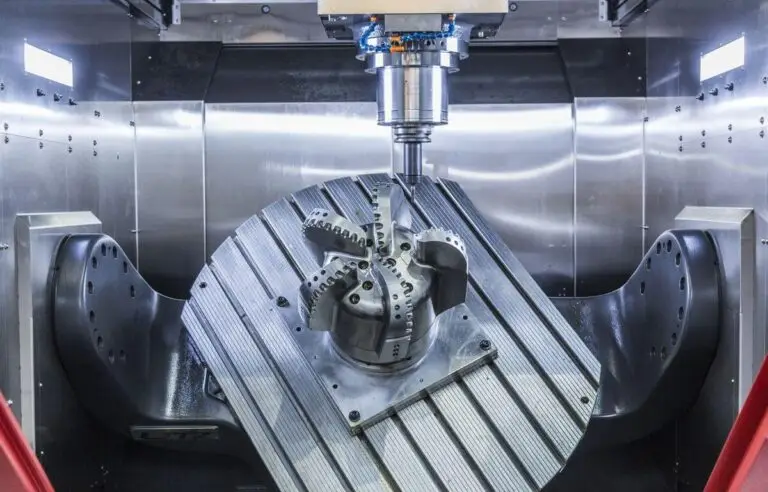

CNC machining can produce parts with high accuracy, but understanding tolerances is key. Tolerances define the allowable variation in part dimensions. Setting them correctly ensures that parts fit, function, and perform as expected—without driving up cost or lead time unnecessarily.

Standard Tolerances for CNC Parts

Most CNC parts can meet tight tolerances by default.

-

- Metals: ±0.005 in (≈0.127 mm)

-

- Plastics: ±0.010 in (≈0.25 mm)

For many prototypes and functional parts, this range is precise enough. To put it in perspective, a sheet of paper is about 0.003 in thick—so even ±0.005 in is already very tight.

When Tighter Tolerances Are Needed

Some features demand closer control:

-

- Bearing fits, press fits, or sealing grooves

-

- Critical alignment features for assemblies

-

- Holes that must be reamed or ground for exact positioning

In these cases, tolerances like ±0.002 in (≈0.05 mm) are possible. With secondary processes such as reaming or grinding, hole accuracy can reach ±0.0005 in (≈0.0127 mm). But tighter tolerances must be clearly specified on the drawing.

The Cost of Tight Tolerances

Closer tolerances come at a price. They often require:

-

- More precise fixturing and slower machining

-

- Extra inspection and measurement

-

- Higher scrap rates if parts fall outside spec

As a result, tighter tolerances can double the machining cost and extend lead times. The best approach is to apply them only to critical dimensions and let other features stay at standard tolerance.

Surface Finish Considerations

CNC machining typically delivers a surface finish around Ra 63 µin (≈1.6 µm) on flat or vertical faces. If smoother surfaces are required, additional finishing steps such as polishing, bead blasting, or coating may be necessary. These also add cost and time, so specify them only where they truly matter.

Best Practices for Designers

-

- Define which dimensions are critical for fit and function.

-

- Use GD&T (Geometric Dimensioning and Tolerancing) where needed to describe position, concentricity, or flatness.

-

- Avoid over-constraining the entire part—reserve close tolerances for the features that require them.

-

- Communicate clearly on drawings so suppliers know what matters most.

By balancing function and manufacturability, you can get parts that perform reliably without unnecessary expense. Understanding CNC machining tolerances helps ensure smoother production and fewer surprises.