CNC machining is a backbone of modern manufacturing. From aircraft engines to medical implants, it provides the accuracy, repeatability, and efficiency that industries rely on. This guide covers the major CNC machining techniques, the machine types that make them possible, and the industries where they play a critical role.

How CNC Machining Works

CNC (Computer Numerical Control) machining turns digital designs into real parts. The process typically follows four stages:

- Design (CAD): A 3D model defines dimensions, tolerances, and features.

- Programming (CAM): The design is translated into G-code for the machine.

- Machining: Tools remove or shape material according to programmed paths.

- Finishing & Inspection: Deburring, polishing, coating, and measurements ensure the part meets requirements.

Core CNC Machining Techniques

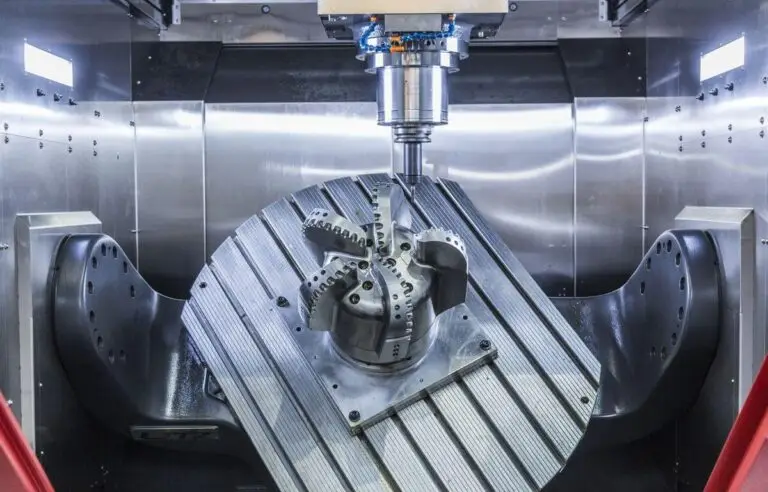

Milling

Rotating multi-point cutters remove material to create flat surfaces, slots, pockets, and complex 3D contours.

- Applications: Aerospace brackets, molds, housings for electronics and medical devices.

Turning

The workpiece rotates while a fixed cutting tool shapes its profile, ideal for cylindrical or conical parts.

- Applications: Shafts, bushings, threaded components, hydraulic parts.

Drilling and Hole-Making

CNC drilling ensures accurate and repeatable holes. Variants include counterboring, countersinking, reaming, and tapping.

- Applications: Mounting holes in automotive frames, coolant channels in molds, electronic connector slots.

Threading

Threads are cut by thread turning or thread milling. Milling is often preferred for accuracy and reduced tool wear.

- Applications: Fasteners, medical implants, aerospace hardware.

Grinding

Abrasive wheels produce high dimensional accuracy and fine surface finishes.

- Applications: Precision tools, hardened steel dies, optics components.

Electrical Discharge Machining (EDM)

Material is eroded by electrical sparks between an electrode and the workpiece, enabling shapes impossible with traditional tools.

- Applications: Mold cavities, turbine components, intricate medical tools.

Advanced Methods

- Multi-axis machining (4–5 axis and beyond): Cuts complex parts in one setup.

- High-speed machining: Reduces cycle time, especially for aluminum.

- Hybrid machining: Combines additive manufacturing with CNC for complex designs plus accurate finishing.

CNC Machine Types

Different machines specialize in different work:

- CNC Mills: Versatile for cutting, drilling, contouring, and tapping.

- CNC Lathes: Cylindrical components such as rods, shafts, and bushings.

- CNC Routers: For plastics, composites, wood, and lightweight metals.

- CNC Plasma & Laser Cutters: Fast sheet-cutting with minimal waste.

- Wire EDM: Thin wire electrode for high-precision internal cuts.

Tooling and Cutting Parameters

Tool choice strongly affects efficiency and quality.

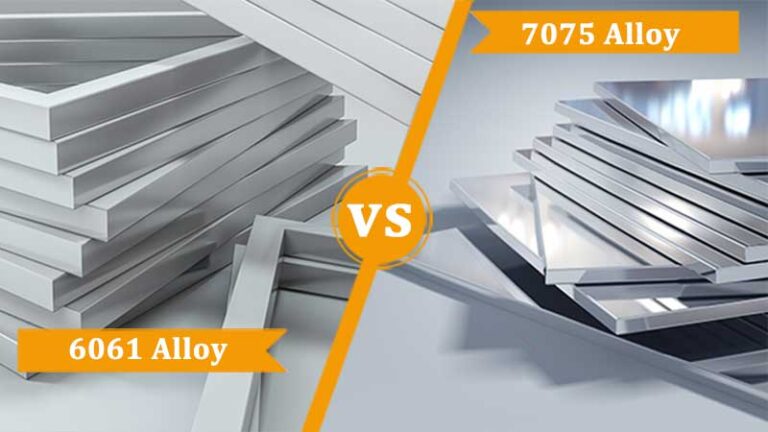

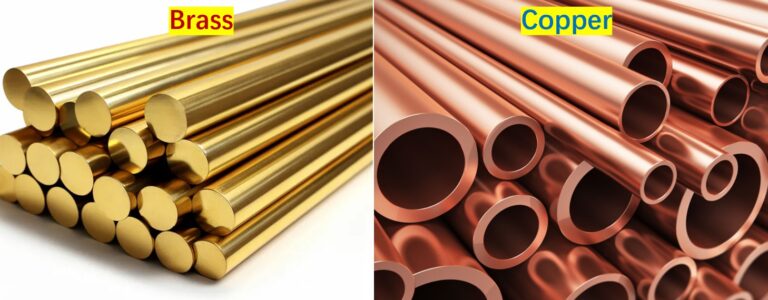

- Carbide tools with TiAlN coatings withstand heat when cutting tough alloys.

- Feeds and speeds must be matched to the material—too fast shortens tool life, too slow wastes cycle time.

- Coolants help control heat and prevent work hardening in metals like titanium.

Finishing Processes

Most CNC parts require finishing:

- Polishing and brushing: For smoothness and aesthetics.

- Anodizing, plating, coating: For corrosion protection and durability.

- Grinding or lapping: For ultra-precise fits.

Key Applications by Industry

Aerospace

- Turbine blades, structural aluminum parts, landing gear components.

- CNC ensures tight tolerances for safety-critical parts.

Automotive

- Engine blocks, transmission housings, custom tooling.

- Machining supports both prototyping and mass production.

Medical

- Bone screws, hip implants, surgical tools.

- Materials like titanium and stainless steel require careful machining.

Electronics

- Heat sinks, housings, connectors.

- CNC enables miniaturization and precision for consumer and industrial electronics.

Defense and Energy

- Firearm components, turbine casings, nuclear plant parts.

- Demands high durability and traceability.

General Manufacturing

- Custom fixtures, molds, industrial machinery parts.

- CNC provides flexibility for small batches and complex geometries.

CNC machining is not defined by one method but by a wide range of techniques. Milling, turning, drilling, grinding, EDM, and multi-axis machining all serve different needs. Combined with the right machines, tooling, and finishing, these methods enable industries to build parts that are accurate, durable, and ready for demanding applications.