Lead time is one of the most critical considerations in CNC machining. Whether you’re developing prototypes or scaling up production, the time it takes to move from design to delivery directly impacts project costs, deadlines, and customer satisfaction. While some delays are unavoidable, many factors that influence lead time can be anticipated and managed.

Below, we break these factors into categories to show how design choices, material decisions, production methods, and workflow management all play a role in how quickly parts are completed.

1. Design-Related Factors

Part complexity

The geometry of a part is one of the biggest drivers of lead time. Simple shapes with standard features usually pass through production quickly. Complex designs, however, require multiple setups, custom tooling, or multi-axis machining, all of which extend machining cycles.

Design for manufacturability (DFM)

Parts designed with manufacturability in mind are faster to produce. Using standard dimensions, avoiding overly tight tolerances, and minimizing unnecessary features cut down on setups and simplify machining.

Tolerance and surface requirements

The tighter the tolerance and smoother the surface finish required, the longer the job will take. These requirements may call for slower machining speeds, additional inspection steps, or secondary finishing processes.

2. Material-Related Factors

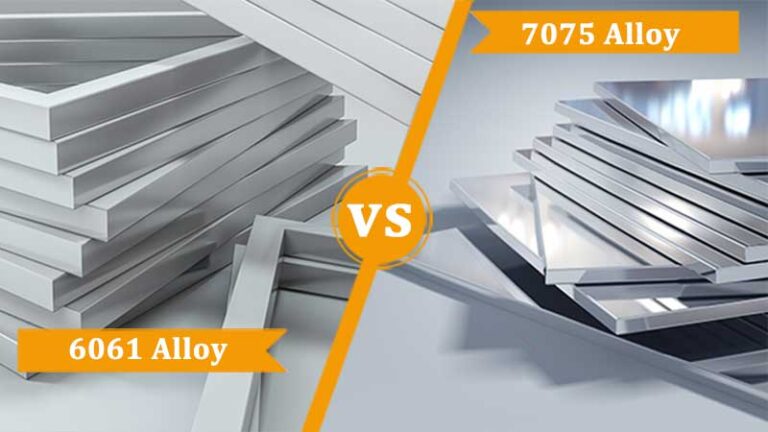

Material availability

Readily available metals like aluminum and common steels shorten lead times. Rare alloys, engineered plastics, or exotic materials can introduce procurement delays that add days or even weeks.

Machinability

Not all materials cut the same way. Easy-to-machine materials reduce tool wear and run faster. Harder or more abrasive materials slow down cutting speeds, increase cycle time, and may require more frequent tool changes.

Supply chain risks

Global logistics also affect availability. Shipping delays, customs clearance, or warehouse inefficiencies can all push back production schedules.

3. Production and Process Factors

Machine setup

Programming, tooling, and calibration must be completed before cutting begins. Complex parts require more preparation, while simple setups let production start quickly.

Tooling and fixtures

Custom tooling or fixtures extend lead time because they need to be designed and fabricated before machining can start.

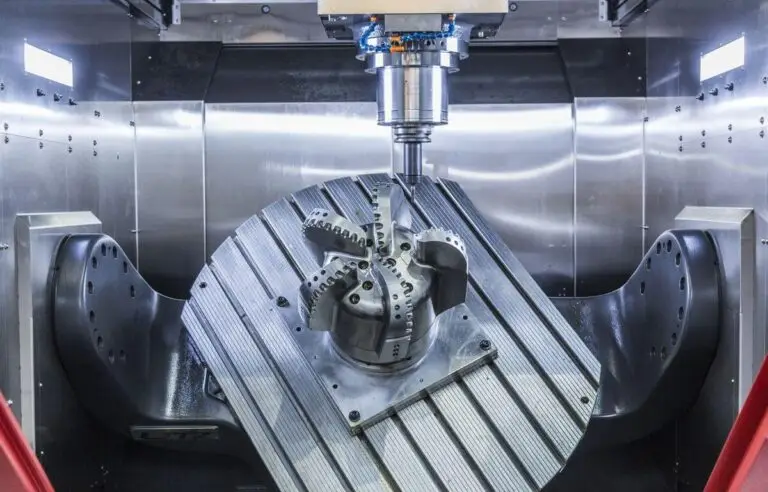

Machining equipment

Machine type also matters. A 5-axis mill can complete complex parts in fewer setups than a 3-axis machine, reducing cycle time. Automated equipment and digital tools further streamline production.

Operator efficiency and material handling

Efficient handling of raw stock and in-process parts prevents bottlenecks. Skilled operators minimize downtime, while automation reduces manual intervention and improves consistency.

4. Quantity and Scheduling Factors

Batch size

One-off parts typically finish faster. Large production runs take longer overall, though they may benefit from economies of scale once machining is underway.

Production capacity and workload

If machines are booked or the shop is operating at full capacity, parts may have to wait in line. High demand or limited capacity often stretches lead times.

5. Post-Processing and Quality Factors

Secondary processes

Heat treatment, anodizing, plating, painting, or other finishes add time—especially if they’re outsourced to external vendors. Depending on the process, these steps can extend lead time by days or even weeks.

Quality control and inspection

Critical parts with tight tolerances or certification requirements undergo more rigorous inspection. While necessary, these checks increase total lead time.

6. Communication and Workflow

Order processing

Delays don’t always come from the shop floor. Manual order processing, unclear drawings, or slow approvals can keep jobs from being scheduled on time.

Client–supplier communication

Fast, clear communication between customer and manufacturer helps avoid missteps and rescheduling. Misunderstandings or late responses can quickly add days to a project.

CNC machining lead time is rarely determined by one single factor. Instead, it’s the combined effect of design complexity, material choices, machine capabilities, finishing requirements, and workflow management. By understanding how these elements interact, engineers and project managers can set realistic timelines and work with suppliers to reduce unnecessary delays.

A proactive approach—designing for manufacturability, selecting available materials, and maintaining open communication—goes a long way toward keeping projects on schedule.