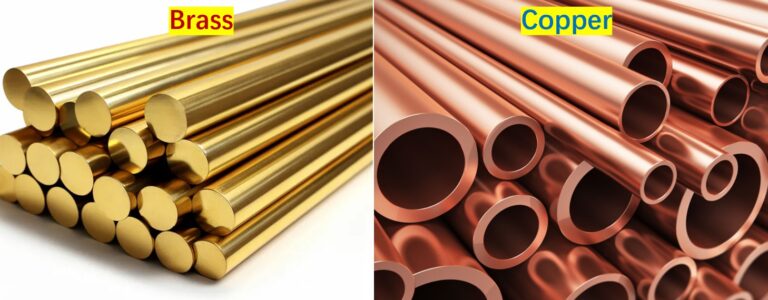

People often mix up brass and copper. Both are widely used in CNC machining, and their reddish and golden tones can look alike at first glance. But once you start working with them, the differences in performance and machinability become clear.

This article breaks down how brass and copper compare in composition, machinability, strength, cost, and applications—so you can see where each material fits best in CNC machining.

Composition and Nature

Brass is an alloy made mainly from copper and zinc, with proportions adjusted to achieve different strengths and properties. Some grades also contain lead or tin to improve machinability. Brass has a bright yellow-gold appearance, which also makes it popular for decorative applications.

Copper, on the other hand, is a pure elemental metal with a distinct reddish-brown color. Its properties stem from purity rather than alloying, which gives it unmatched electrical and thermal conductivity.

Mechanical Properties

Brass is stronger than copper and offers lower friction, making it more durable under mechanical stress. It resists wear and can handle moderate corrosion in industrial or marine environments.

Copper is softer and more ductile. While it can deform easily under stress, this same ductility makes it suitable for forming and bending operations.

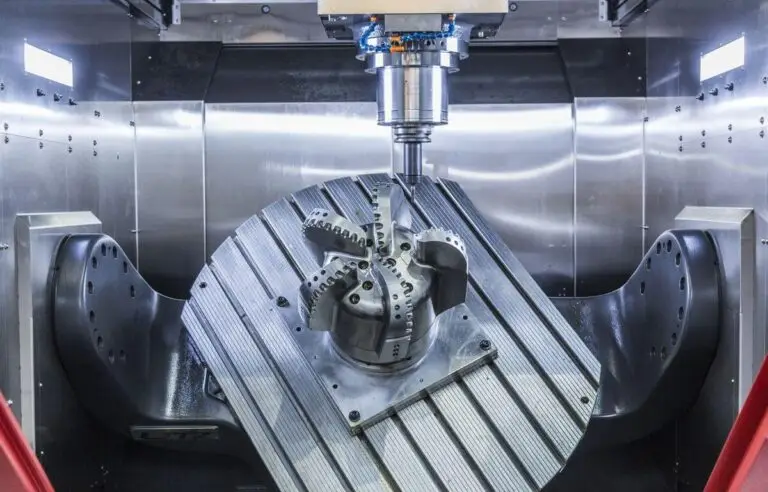

Machinability

Brass is considered one of the easiest metals to machine. It produces short, clean chips, reduces tool wear, and allows efficient cutting without gumming up the tool. In fact, free-cutting brass (C36000) is often used for CNC demonstrations because of how smoothly it machines.

Copper, by contrast, is challenging. It tends to produce long, stringy chips, gums up tools, and generates burrs that require extra finishing. These traits shorten tool life and increase machining costs.

Cutting Speed and Tool Life

CNC machining of brass allows for cutting speeds two to three times faster than copper. Tool life is also longer—often three to five times—because brass reduces friction and tool loading. This directly translates into faster production and lower tooling expenses.

Surface Finish and Accuracy

Brass parts typically come off the machine with excellent surface finishes and tight tolerances. Dimensional accuracy is easier to achieve because the material resists deformation.

Copper often needs additional polishing or deburring to meet finish requirements. Its ductility can cause edges to smear and tolerances to drift during machining.

Thermal and Electrical Conductivity

This is where copper stands out. It has superior thermal and electrical conductivity, making it the go-to choice for wiring, heat exchangers, busbars, and other electrical or thermal components.

Brass offers moderate conductivity but balances it with better strength and wear resistance, making it useful for connectors and fittings where both electrical performance and durability matter.

Corrosion Resistance

Brass generally performs better than pure copper in corrosive environments. Naval brass (C46400), for example, is engineered for marine applications, combining corrosion resistance with strength.

Copper resists oxidation but can develop a patina over time, which in some cases is desirable for aesthetics but not for mechanical parts.

Cost and Availability

Brass is usually more cost-effective for CNC machining. Faster cutting speeds and reduced tool wear mean shorter cycle times and lower production costs.

Copper itself is not excessively expensive as a raw material, but the higher machining costs—longer cycles, more tool changes, and extra finishing—make projects more expensive overall.

Grades and Variants

Brass grades for machining:

- C36000 (free-cutting brass, high machinability, contains lead)

- C46400 (naval brass, strong corrosion resistance)

- C48500 (leaded naval brass, combines machinability and durability)

Copper grades for machining:

- C10100 (oxygen-free, excellent conductivity)

- C11000 (electrolytic tough pitch, widely available)

Applications

Brass: gears, valves, pipe fittings, bushings, electrical connectors, instrument components, decorative parts.

Copper: electrical wiring, busbars, heat exchangers, cooling systems, and parts where conductivity is critical.

Environmental and Regulatory Concerns

Traditional free-cutting brass contains lead, which improves machinability but faces increasing restrictions under RoHS and similar regulations. Many manufacturers now offer lead-free or bismuth-modified alternatives to meet compliance requirements.

Chip Formation and Waste Management

Brass generates short, manageable chips, simplifying cleanup and reducing the risk of tool damage.

Copper’s long, stringy chips require careful chip management to avoid tangling, which can slow machining and damage tooling.

Brass vs Copper

| Aspect | Brass | Copper |

|---|---|---|

| Composition | Alloy of copper + zinc (may include lead or tin) | Pure elemental metal (reddish-brown) |

| Machinability | Excellent; short chips, easy cutting, long tool life | Difficult; gumming, burrs, long chips, shorter tool life |

| Cutting Speed | 2–3× faster than copper | Slower, requires more careful machining |

| Strength & Wear | Stronger, lower friction, better wear resistance | Softer, more ductile, prone to deformation |

| Surface Finish | Smooth finishes, tight tolerances, minimal deformation | Needs more polishing and finishing |

| Conductivity | Moderate thermal & electrical conductivity | Excellent conductivity, ideal for electrical & thermal parts |

| Corrosion Resistance | Good, especially naval brass in marine use | Moderate, develops patina over time |

| Cost Efficiency | Lower machining cost, faster production | Higher machining cost despite similar raw material price |

| Common Grades | C36000 (free-cutting), C46400 (naval), C48500 (leaded naval) | C10100 (oxygen-free), C11000 (tough pitch) |

| Applications | Gears, valves, connectors, fittings, decorative components | Wiring, busbars, heat exchangers, cooling systems |

Brass and copper each bring unique advantages to CNC machining. Brass is often chosen when machinability, durability, and cost control matter most, while copper is preferred where top electrical or thermal performance is required. Knowing where each material fits best helps avoid overengineering and keeps projects practical.