Aluminum 6061 and 6082 belong to the same 6000-series Al-Mg-Si family, but they do not behave the same once they reach the CNC machine. Both alloys offer a balance of strength, corrosion resistance and weight, yet their mechanical properties, machining response and structural performance differ enough that engineers rarely treat them as perfect substitutes.

A simple way to describe them is this: 6061 is the versatile CNC workhorse, while 6082 is the structural option when loads and long-term durability matter more than machining convenience.

Composition and what it means during machining

Both alloys use magnesium and silicon to form Mg2Si, which provides strength after heat treatment.

The key difference is manganese. 6082 contains several times more manganese than 6061. This strengthens the grain structure and is the main reason why 6082-T6 reaches higher strength levels. It also explains why 6082 is slightly harder on tools and tends to require lower cutting speeds.

6061, with its lower manganese content, remains easier to extrude, easier to form and smoother to machine, especially in deep pockets or long continuous cuts.

Strength, hardness and stiffness

Mechanical test ranges for typical T6 temper show clear differences:

-

- 6061-T6 tensile strength is often around 280–310 MPa

-

- 6082-T6 frequently reaches 300–340 MPa

-

- Yield strength shows a similar gap, with 6082 generally 10–15% higher

-

- Hardness is close, but 6082 sits slightly higher in many batches

-

- Both alloys share a similar elastic modulus, so stiffness under load feels similar

For CNC components that carry meaningful loads—frames, brackets, lifting parts, linkages—6082 provides extra margin against permanent deformation.

6082 also shows slightly better shear and fatigue performance, which matters for parts exposed to repeated cycles or vibration.

6061 remains more than adequate for most mechanical housings, fixtures, prototypes and mid-strength components where machining efficiency matters.

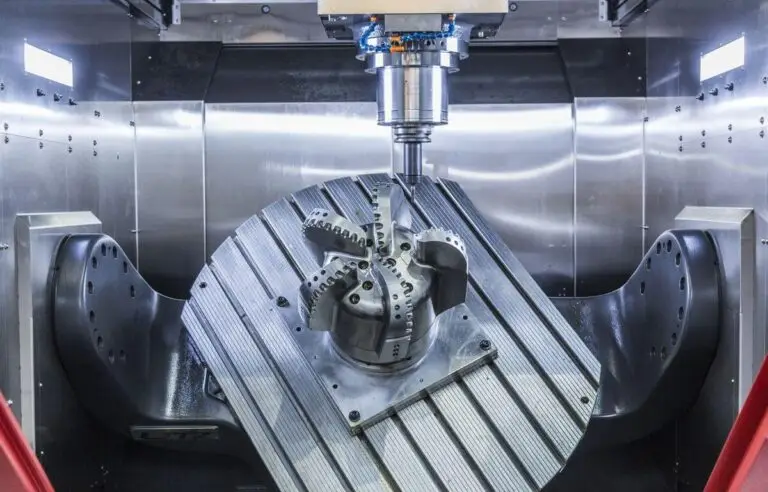

Machinability and CNC performance

Machine shops often describe 6061-T6 as a predictable alloy.

It supports high spindle speeds, produces clean chips and gives uniform surface finish across milling, turning and drilling. Its behavior rarely surprises the operator, which is one reason it dominates general CNC work.

6082-T6 machines well but requires more attention. Its higher strength increases tool wear, and it often benefits from reduced feed rates and more rigid setups. During profiling or slotting, cutters may experience more resistance, especially when removing large amounts of material.

For simple structural profiles, this difference is small.

For complex 3-axis and 5-axis machining, 6061 usually saves time, tools and cost.

Weldability, distortion and post-machining stability

Both alloys are weldable, but 6061 usually performs better in real workshops.

It responds more predictably to heat, especially when the design includes multiple welded joints followed by machining.

6082 can also be welded, but it requires closer control of heat input and joint preparation to avoid local softening or distortion.

This is why many welded assemblies that still require accurate CNC finishing lean toward 6061 unless strength requirements point firmly toward 6082.

In terms of dimensional stability during machining, both are reliable in T6 condition.

However, 6061 tends to release less residual stress when large volumes of material are removed.

6082’s higher strength sometimes means slightly more movement during heavy machining, especially in thicker blocks.

Corrosion behavior and outdoor service

Both alloys resist corrosion well, especially after anodizing.

In practical use:

-

- 6061 is sufficient for most outdoor, industrial and automotive environments

-

- 6082 may offer a slight advantage in long-term marine or high-humidity exposure due to its higher strength and microstructure

The difference is not dramatic, but engineers working with marine hardware often specify 6082 when strength and exposure risks stack together.

Cost, supply and availability

6061 remains one of the most available aluminum alloys worldwide. It is stocked in plate, bar, tube and sheet, with consistent pricing and short lead times.

Its machining cost is also lower, since it cuts faster and wears tools more slowly.

6082 is more common in regions with a strong focus on structural aluminum, especially Europe. Prices tend to be higher, and machining takes longer, so total part cost rises accordingly.

For cost-sensitive CNC components, 6061 is usually the preferred choice.

Aluminum 6061 vs 6082 Comparison for CNC Machining

| Aspect | 6061 (for CNC machining) | 6082 (for CNC machining) |

|---|---|---|

| Strength | Medium–high strength; adequate for most mechanical parts | Higher tensile and yield strength; better for load-bearing parts |

| Fatigue / Shear | Good for general use | Slightly better fatigue and shear resistance |

| Machinability | Easier to machine; cleaner chips; faster cutting speeds | Harder on tools; lower cutting speeds; more rigid setups needed |

| Tool Wear | Lower | Higher due to higher strength |

| Weldability | More forgiving; predictable heat-affected zone | Weldable but needs better heat control |

| Formability | Better bending and forming | Less suitable for tight bends |

| Surface Finish | More consistent finish and anodizing color | Finish is good but may vary slightly in color |

| Dimensional Stability | Very stable during heavy material removal | Stable but may release slightly more internal stress |

| Corrosion Resistance | Good for most environments | Often preferred for harsher outdoor/marine exposure |

| Availability | Widely stocked globally | More common in regions using EN standards |

| Material Cost | Lower | Higher |

| Best Use Cases | Prototypes, fixtures, housings, welded parts, cost-sensitive CNC jobs | Structural frames, high-load components, outdoor/marine hardware |

Typical CNC applications

6061 works well for:

-

- Brackets, housings, enclosures, fixtures and general CNC parts

-

- Prototypes and small-batch production

-

- Components involving both machining and welding

-

- Consumer, mechanical and automotive hardware

-

- Parts requiring complex geometries or deep machining

6082 suits:

-

- Load-bearing frames, beams and structural units

-

- Parts exposed to repeated stress or vibration

-

- Outdoor and marine assemblies where higher strength is beneficial

-

- Applications where a higher strength-to-weight ratio matters

-

- Safety-critical designs where added margin is needed

Design guidance

Choose 6061 when speed, cost and geometric complexity matter. It is easy to machine, stable, widely available and strong enough for most mechanical uses.

Choose 6082 when the part must handle higher loads, repeated shock or harsh environments, and when the design benefits from a stronger structural base even if machining becomes slower and more expensive.