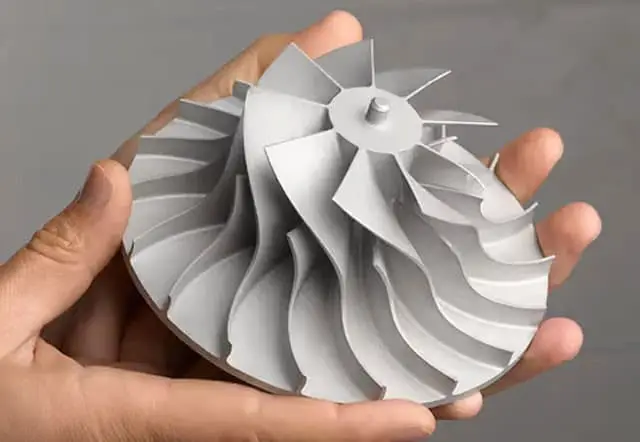

Pre-production prototypes are a crucial step before full-scale manufacturing. Discover why CNC machining is the best choice for creating these prototypes.

Benefits of CNC Machining for Pre-Production Prototypes

Accuracy

- Design Precision: CNC machining ensures that pre-production prototypes closely match the final product design. This high level of accuracy is essential for verifying the design’s feasibility and functionality.

- Early Issue Identification: Accurate prototypes help identify and correct design issues early in the development process, preventing costly errors during mass production.

Scalability

- Small Production Runs: CNC machining is ideal for producing small batches of prototypes. This scalability allows for thorough testing of manufacturing processes and adjustments as needed.

- Market Validation: Creating a limited number of prototypes enables companies to gather market feedback and validate the product concept before committing to full-scale production.

Cost Efficiency

- Avoids Expensive Tooling: CNC machining does not require the creation of expensive molds or tooling, significantly reducing initial costs.

- Realistic Previews: Pre-production prototypes provide a realistic preview of the final product, allowing for better decision-making without the need for large-scale production investments.

Importance of Pre-Production Prototypes

Risk Minimization

- Design Refinement: By creating prototypes that closely resemble the final product, companies can refine and perfect their designs, minimizing the risk of defects or issues during mass production.

- Process Optimization: Prototypes allow manufacturers to optimize their production processes, ensuring efficiency and quality in the final product.

Market Readiness

- Customer Feedback: Prototypes can be used to gather valuable feedback from potential customers or stakeholders, ensuring the product meets market needs and expectations.

- Regulatory Compliance: Pre-production prototypes help ensure that the product meets industry standards and regulatory requirements before it goes to market.

Resource Management

- Efficient Use of Resources: By identifying and addressing potential issues early, companies can avoid wasting resources on flawed designs or inefficient manufacturing processes.

- Budget Control: Pre-production prototypes help keep the project within budget by reducing unexpected costs associated with design changes or process adjustments.

Using CNC machining for pre-production prototypes offers a combination of accuracy, scalability, and cost efficiency, making it an essential part of the product development process. By leveraging these benefits, companies can ensure their products are ready for the market, minimizing risks and optimizing manufacturing processes.