CNC machining has redefined manufacturing, offering unmatched precision and efficiency. Imagine bringing complex designs to life effortlessly. This technology is a game-changer for modern production. Let’s break down the key benefits of CNC machining and why it’s essential for today’s manufacturers.

What is CNC Machining?

CNC (Computer Numerical Control) machining uses computer software to control machinery, enabling precise cutting tool manipulation. This automated process ensures high accuracy and repeatability, making it ideal for producing detailed parts.

Key Benefits of CNC Machining

High Precision

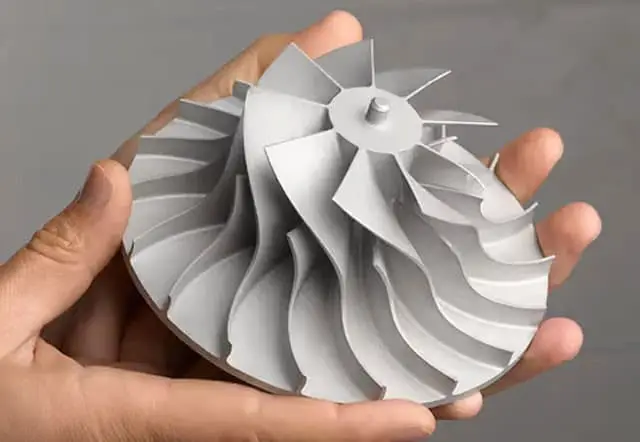

Tight Tolerances and Intricate Designs: CNC machines achieve extremely tight tolerances, essential for high-precision parts. This capability allows creating intricate designs that manual machining can’t match.

Consistent Quality: CNC machining consistently produces high-quality parts. Every production run, regardless of size, maintains the same high standards, reducing defects and ensuring reliability.

Increased Efficiency

Reduced Production Time: CNC machining drastically cuts production time by automating the process. This reduces the need for manual intervention, speeding up production cycles and allowing quicker turnarounds.

Lower Labor Costs: Automation means fewer labor hours, translating to lower costs. Operators can oversee multiple machines simultaneously, boosting productivity and reducing overall expenses.

Prototyping and Large-Scale Production: CNC machining handles both prototyping and large-scale production runs. This flexibility allows manufacturers to quickly transition from design to mass production without major adjustments.

Versatility

Wide Range of Materials: CNC machines work with various materials, including metals (aluminum, steel, titanium), plastics, and composites. This versatility makes CNC machining suitable for multiple industries.

Industry Applications: CNC machining is crucial in aerospace (precision components, structural parts), automotive (engine parts, custom components), and medical devices (surgical instruments, prosthetics). Its broad applicability highlights its importance in modern manufacturing.

Enhancing Your Manufacturing with CNC Machining

Embracing CNC machining can significantly enhance your manufacturing processes. Its precision and efficiency are unparalleled, making it a crucial tool for modern production. By incorporating CNC technology, manufacturers can improve product quality, increase production speed, and reduce costs, gaining a competitive edge in the marketplace.