Hey there, fellow manufacturing enthusiasts! Today, we’re diving deep into the world of plastic injection molding – a game-changer in the realm of modern manufacturing. Whether you’re in automotive, healthcare, or electronics, mastering the nuances of plastic injection molding can skyrocket your production efficiency and precision.

What is Plastic Injection molding?

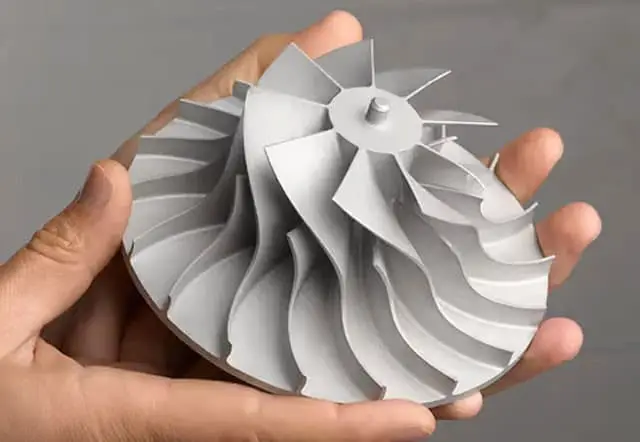

Plastic injection molding isn’t just a process; it’s a revolution. Imagine taking molten plastic and injecting it into a custom mold. The result? Complex, precise plastic parts crafted with exceptional accuracy and consistency. This method is a powerhouse in the manufacturing world, enabling you to bring your most intricate designs to life.

Why Choose Plastic Injection Molding?

High Precision and Consistency

Achieve Complex Shapes: Plastic injection molding allows you to create intricate shapes that other manufacturing methods can only dream of. We’re talking about designs that push the boundaries of what’s possible.

Tight Tolerances: Need parts that meet strict tolerances? This process has you covered. It’s ideal for industries where precision is non-negotiable, like automotive and healthcare.

Consistent Quality: Consistency is key, especially when you’re producing parts at scale. Injection molding ensures uniformity across large production runs, so every part meets your high standards.

Cost-Effective Production

Low Cost Per Part: Once you’ve created the initial mold, the cost per part plummets. This makes plastic injection molding a cost-effective solution for high-volume production.

Reduced Material Waste: Let’s be real – waste is costly. This process minimizes material waste, making it both cost-efficient and environmentally friendly.

Versatility in Applications

Automotive Industry: From dashboards to engine components, plastic injection molding is a staple in the automotive industry. It ensures high durability and precision, keeping vehicles running smoothly.

Healthcare Sector: In healthcare, precision is paramount. Injection molding is crucial for creating medical devices, surgical instruments, and other critical components with unmatched accuracy and reliability.

Electronics and Consumer Goods: Need precision and scalability for electronic housings, connectors, and consumer goods? Look no further. This process delivers both, making it perfect for a wide range of applications.

How Plastic Injection Molding Enhances Manufacturing Capabilities

Speed and Efficiency: Time is money, right? Injection molding is highly automated, slashing production time and labor costs. This efficiency is a boon for large-scale manufacturing projects.

Material Versatility: You’ve got options! A wide range of thermoplastics can be used, allowing you to choose the best material for your specific application. This enhances product performance and longevity.

Customization Options: From design to color to material properties, injection molding offers extensive customization. You can meet specific client requirements effectively, giving you a competitive edge.

Leveraging Plastic Injection Molding for Optimal Results

By now, it’s clear – understanding and leveraging the advantages of plastic injection molding can transform your manufacturing processes. Its precision, efficiency, and versatility make it an ideal choice for producing high-quality plastic products across various industries.

Whether you’re looking to enhance your automotive production line, innovate in healthcare device manufacturing, or scale up electronics production, plastic injection molding is your go-to solution. Embrace this technology to stay ahead in the competitive manufacturing landscape.