Rapid prototyping is essential for testing and refining designs quickly. Learn how CNC machining plays a pivotal role in creating precise and functional prototypes efficiently.

Advantages of CNC Machining for Rapid Prototyping

Speed

- Quick Production: CNC machining allows for the rapid production of prototypes, helping you meet tight deadlines and accelerate the development cycle.

- Rapid Iteration: Quickly produce multiple iterations of a design, facilitating continuous testing and refinement.

Precision

- High Accuracy: CNC machining provides exceptional accuracy, ensuring that prototypes are true to the design specifications. This precision is crucial for testing functionality and fit.

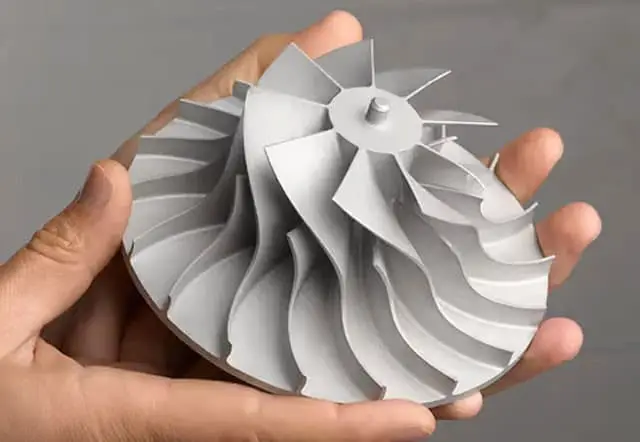

- Detailed and Complex Designs: Capable of producing intricate and complex designs that other prototyping methods might struggle with.

Cost-Effectiveness

- Small Quantities: CNC machining is ideal for producing small quantities of prototypes without the need for expensive molds or setup costs associated with other manufacturing processes.

- Early Flaw Detection: By creating accurate prototypes, design flaws can be identified and corrected early in the development process, reducing overall costs and time to market.

Utilizing CNC Machining for Rapid Prototyping

By leveraging CNC machining for rapid prototyping, you can significantly accelerate your product development process. The combination of speed, precision, and cost-effectiveness makes CNC machining an invaluable tool for innovators looking to bring their ideas to life quickly and efficiently.

Benefits for Product Development

- Accelerated Development: Faster turnaround times mean quicker feedback and shorter development cycles.

- High-Quality Prototypes: Precise and functional prototypes help in making informed decisions and improvements.

- Reduced Costs: Early identification of design flaws reduces the need for costly revisions and reworks later in the development process.

Embrace CNC machining for your rapid prototyping needs to enhance your product development workflow, ensuring high-quality prototypes that lead to successful final products.