Functional prototypes are critical for testing the real-world performance of your designs. Discover how CNC machining helps create reliable and high-quality functional prototypes.

Advantages of CNC Machining for Functional Prototypes

Material Versatility

- Wide Range of Materials: CNC machining can work with a variety of materials, including metals (like aluminum, stainless steel, and titanium), plastics (such as ABS, PVC, and polycarbonate), and composites (like carbon fiber and fiberglass).

- Material Selection: You can choose materials that closely match the properties of the final product, ensuring that the prototype behaves similarly during testing.

High Precision

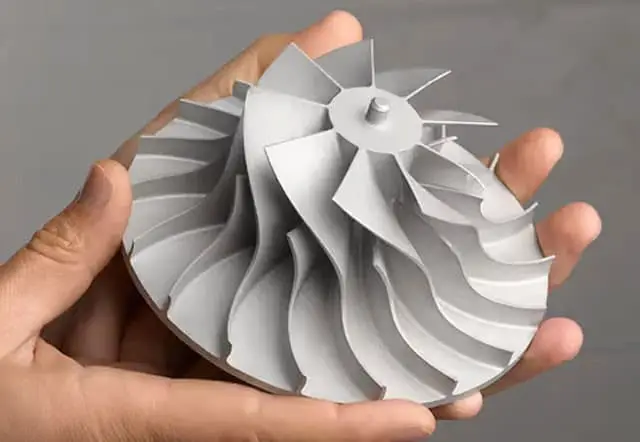

- Exact Specifications: CNC machining delivers high precision, ensuring that prototypes meet exact design specifications. This precision is essential for accurate testing and validation.

- Detailed Features: Capable of producing intricate and complex designs, which is crucial for testing all aspects of the prototype’s functionality.

Durability

- Robust Prototypes: CNC machining produces durable prototypes that can withstand rigorous testing conditions. This durability is important for stress, fatigue, and performance evaluations.

- Real-World Testing: Functional prototypes created with CNC machining can endure real-world testing, providing valuable insights into how the final product will perform under various conditions.

Benefits of CNC Machining for Functional Prototypes

Insightful Testing

- Mechanical and Physical Properties: High-precision prototypes facilitate thorough testing of mechanical and physical properties, allowing for detailed analysis and refinement of the design.

- Performance Evaluation: Durable prototypes are ideal for performance evaluations, ensuring the final product meets desired standards before mass production.

Improved Product Development

- Design Refinement: Functional prototypes allow for iterative testing and refinement, helping to identify and address design flaws early in the development process.

- Cost Efficiency: Creating accurate and reliable prototypes reduces the risk of costly revisions and reworks during later stages of product development.

By leveraging CNC machining for functional prototypes, you gain a powerful tool to enhance your product development process. The material versatility, high precision, and durability of CNC-machined prototypes provide the necessary foundation for rigorous testing and design refinement, ultimately leading to a successful final product.