Selecting the appropriate materials and finishes is crucial in CNC machining. This article helps you understand the options available and their impact on your final product.

Materials

Metals

- Aluminum: Known for its light weight, durability, and excellent machinability. Ideal for aerospace, automotive, and consumer electronics.

- Stainless Steel: Offers high strength, corrosion resistance, and is suitable for medical devices, food processing, and chemical industries.

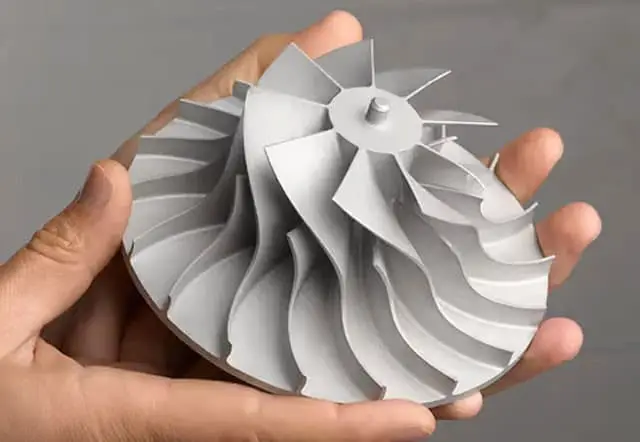

- Titanium: Known for its high strength-to-weight ratio and corrosion resistance. Commonly used in aerospace, medical implants, and high-performance engineering applications.

Benefits: Durability, strength, and corrosion resistance.

Plastics

- ABS: A versatile and cost-effective plastic known for its impact resistance and toughness. Often used in automotive parts, consumer products, and electronic enclosures.

- PVC: Known for its chemical resistance and versatility, making it ideal for pipes, fittings, and valves.

- Polycarbonate: Offers high impact resistance and transparency. Commonly used in safety equipment, automotive components, and electronics.

Benefits: Lightweight, cost-effective, and versatile.

Composites

- Carbon Fiber: Known for its high strength-to-weight ratio and stiffness. Widely used in aerospace, sports equipment, and high-performance automotive parts.

- Fiberglass: Offers good strength and durability, often used in boat hulls, automotive body panels, and sporting goods.

Benefits: High strength-to-weight ratio and excellent performance.

Finishes

Anodizing

- Adds a protective and decorative oxide layer on metals, enhancing corrosion resistance and aesthetic appeal. Commonly used for aluminum parts in aerospace, automotive, and consumer electronics.

Powder Coating

- Provides a durable, high-quality finish that is resistant to scratches, chipping, and fading. Suitable for a wide range of metal and some plastic parts used in automotive, appliance, and industrial applications.

Plating

- Enhances surface properties like corrosion resistance, conductivity, and wear resistance. Types include nickel plating, chrome plating, and gold plating. Used in electronics, automotive, and aerospace industries.

Choosing the right materials and finishes is essential for achieving the desired performance and aesthetics of your CNC machined parts. Consult with experts to make informed decisions for your projects, ensuring that your parts meet the necessary specifications and standards.

By carefully selecting the appropriate materials and finishes, you can optimize the performance, durability, and appearance of your CNC machined parts, ultimately leading to better products and greater customer satisfaction.