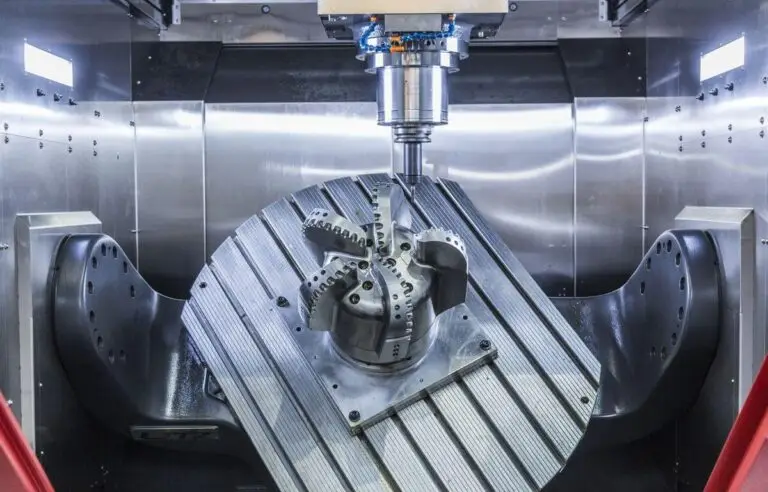

The choice of material is one of the most important steps in CNC machining. It determines not only how strong or durable a part will be, but also how easily it can be produced, finished, and delivered on schedule. The right material balances function, machinability, cost, and availability.

What to Consider When Selecting a Material

-

- Mechanical properties: Tensile strength, hardness, and ductility define whether a part can handle loads or impacts.

-

- Machinability: Easier-to-machine materials reduce tool wear, cycle time, and cost, while delivering better surface finish.

-

- Thermal behavior:

-

- High thermal conductivity (aluminum, copper) helps dissipate heat during cutting.

-

- Low thermal expansion (stainless steel, some alloys) ensures dimensional stability.

-

- Thermal behavior:

-

- Corrosion resistance: Stainless steel, titanium, and anodized aluminum excel in harsh or marine environments.

-

- Weight: Lightweight choices like aluminum, magnesium, or plastics are ideal for aerospace, drones, and robotics.

-

- Cost and availability: A raw material that is cheaper but difficult to machine may end up more expensive overall. Supply chain stability also matters for lead time.

-

- Finishing compatibility: Some finishes—anodizing, passivation, plating—work only with certain materials.

-

- Compliance: Medical, food, and aerospace industries often require RoHS, FDA, or other certifications.

Common CNC Machining Materials

Metals

-

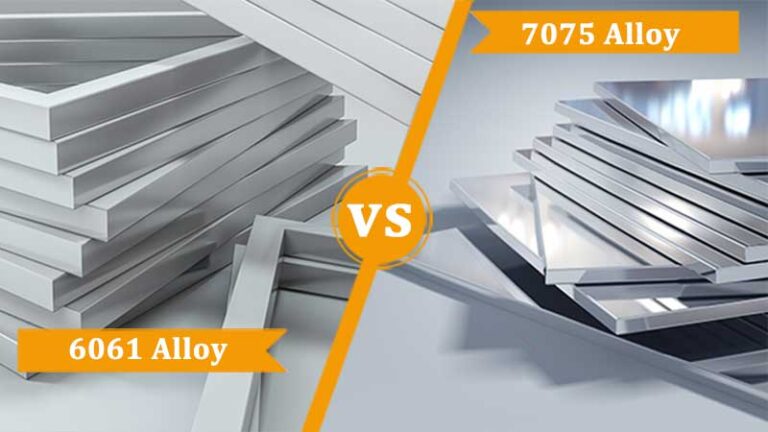

- Aluminum 6061: Lightweight, corrosion-resistant, and easy to machine; widely used for housings and prototypes.

-

- Aluminum 7075: Stronger and tougher than 6061, often used in aerospace and automotive.

-

- Stainless Steel 304: General-purpose stainless steel with good corrosion resistance; food-grade.

-

- Stainless Steel 316/316L: Superior corrosion resistance, suitable for marine and medical uses.

-

- Mild Steel: Strong, inexpensive, weldable; common for structural parts.

-

- Tool Steel: High hardness and wear resistance, heat-treatable for molds and dies.

-

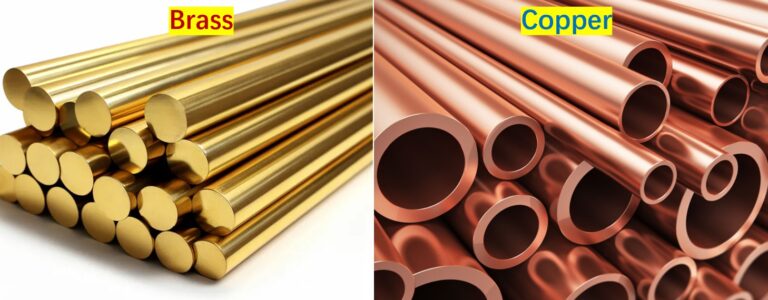

- Brass: Excellent machinability, corrosion resistance, and appearance; used in fittings and decorative parts.

-

- Copper: Exceptional electrical and thermal conductivity; common in electrical components.

-

- Titanium: High strength-to-weight ratio, biocompatible, corrosion-resistant; favored in medical and aerospace.

Plastics

-

- ABS: Low cost, easy to machine; good for prototypes and enclosures.

-

- Nylon (PA): Strong, wear-resistant, and self-lubricating; used for gears and bushings.

-

- Polycarbonate (PC): Transparent, impact-resistant; common for housings and protective covers.

-

- PEEK: High-performance thermoplastic; withstands high heat and chemicals; used in aerospace and medical devices.

Material Comparison Table

| Material | Key Properties | Advantages | Common Applications |

|---|---|---|---|

| Aluminum 6061 | Light, corrosion-resistant, machinable | Affordable, versatile | Prototypes, housings, aerospace |

| Aluminum 7075 | High strength, fatigue-resistant | Stronger than 6061 | Aerospace, automotive, tooling |

| Stainless 304 | Strong, corrosion-resistant | Food-grade, widely available | Food equipment, consumer parts |

| Stainless 316 | Superior corrosion resistance | Resistant to salt & chemicals | Marine, medical, pharmaceutical |

| Mild Steel | Strong, inexpensive | Easy to weld and machine | Structural and automotive parts |

| Tool Steel | Hard, wear-resistant, heat-treatable | Long service life | Dies, molds, cutting tools |

| Brass | Easy to machine, aesthetic | Corrosion-resistant, smooth finish | Fittings, decorative components |

| Copper | High conductivity, soft | Excellent electrical properties | Connectors, heat exchangers |

| Titanium | Strong, light, biocompatible | High corrosion resistance | Medical implants, aerospace parts |

| ABS | Lightweight, inexpensive | Easy prototyping material | Enclosures, prototypes |

| Nylon | Tough, wear-resistant | Self-lubricating | Gears, bushings, moving parts |

| Polycarbonate | Transparent, impact-resistant | Tough and versatile | Covers, protective housings |

| PEEK | High-performance, chemical resistant | Heat and wear resistant | Medical, aerospace, electronics |

Matching Material to Applications

-

- Load-bearing parts → Tool steel, titanium, or high-strength aluminum.

-

- Corrosive environments → Stainless steel 316L, titanium, anodized aluminum.

-

- Lightweight needs → Aluminum, magnesium, or plastics.

-

- Electrical conductivity → Copper or brass.

-

- Insulation or sterilization → Plastics such as PEEK, PTFE, or ABS.

Practical Advice

-

- Prototype and test before scaling production.

-

- Apply high-performance materials only where needed—avoid overspecifying.

-

- Consult CNC manufacturers to align material choice with machining capabilities.

-

- Plan ahead for surface treatments, regulatory compliance, and supply chain realities.

Material choice in CNC machining is about trade-offs: strength vs weight, machinability vs durability, cost vs performance. By understanding how materials behave under machining and in service, you can make informed choices that keep production efficient and parts reliable.